User research at BESSY II: Graphite electrodes for rechargeable batteries investigated

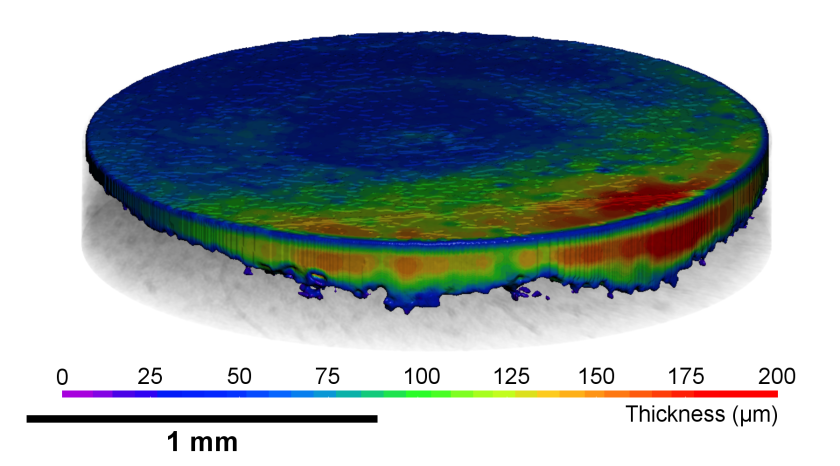

The tomogram during the charging process shows the spatially resolved changes in the graphite electrode thickness of a rechargeable aluminium ion battery in a discharged and charged state. © HZB

Rechargeable graphite dual ion batteries are inexpensive and powerful. A team of the Technical University of Berlin has investigated at the EDDI Beamline of BESSY II how the morphology of the graphite electrodes changes reversibly during cycling (operando). The 3D X-ray tomography images combined with simultaneous diffraction now allow a precise evaluation of the processes, especially of changes in the volume of the electrodes. This can help to further optimise graphite electrodes.

Published in Advanced Functional Materials (2020); Simultaneous X‐Ray Diffraction and Tomography Operando Investigation of Aluminum/Graphite Batteries; Giuseppe Antonio Elia, Giorgia Greco, Paul Hans Kamm, Francisco García‐Moreno, Simone Raoux, Robert Hahn

DOI: 10.1002/adfm.202003913

Abstract: Rechargeable graphite dual‐ion batteries are extremely appealing for grid‐level stationary storage of electricity, thanks to the low‐cost and high‐performance metrics, such as high‐power density, energy efficiency, long cycling life, and good energy density. An in‐depth understanding of the anion intercalation mechanism in graphite is fundamental for the design of highly efficient systems. In this work, a comparison is presented between pyrolytic (PG) and natural (NG) graphite as positive electrode materials in rechargeable aluminum batteries, employing an ionic liquid electrolyte. The two systems are characterized by operando synchrotron energy‐dispersive X‐ray diffraction and time‐resolved computed tomography simultaneously, establishing a powerful characterization methodology, which can also be applied more in general to carbon‐based energy‐related materials. A more in‐depth insight into the AlCl4−/graphite intercalation mechanism is obtained, evidencing a mixed‐staged region in the initial phase and a two‐staged region in the second phase. Moreover, strain analysis suggests a correlation between the irreversibility of the PG electrode and the increase of the inhomogenous strain. Finally, the imaging analysis reveals the influence of graphite morphology in the electrode volume expansion upon cycling.

red.

https://www.helmholtz-berlin.de/pubbin/news_seite?nid=22334;sprache=en

- Copy link

-

Ultrafast dissociation of molecules studied at BESSY II

For the first time, an international team has tracked at BESSY II how heavy molecules – in this case bromochloromethane – disintegrate into smaller fragments when they absorb X-ray light. Using a newly developed analytical method, they were able to visualise the ultrafast dynamics of this process. In this process, the X-ray photons trigger a "molecular catapult effect": light atomic groups are ejected first, similar to projectiles fired from a catapult, while the heavier atoms - bromine and chlorine - separate more slowly.

-

Battery research with the HZB X-ray microscope

New cathode materials are being developed to further increase the capacity of lithium batteries. Multilayer lithium-rich transition metal oxides (LRTMOs) offer particularly high energy density. However, their capacity decreases with each charging cycle due to structural and chemical changes. Using X-ray methods at BESSY II, teams from several Chinese research institutions have now investigated these changes for the first time with highest precision: at the unique X-ray microscope, they were able to observe morphological and structural developments on the nanometre scale and also clarify chemical changes.

-

BESSY II: New procedure for better thermoplastics

Bio-based thermoplastics are produced from renewable organic materials and can be recycled after use. Their resilience can be improved by blending bio-based thermoplastics with other thermoplastics. However, the interface between the materials in these blends sometimes requires enhancement to achieve optimal properties. A team from the Eindhoven University of Technology in the Netherlands has now investigated at BESSY II how a new process enables thermoplastic blends with a high interfacial strength to be made from two base materials: Images taken at the new nano station of the IRIS beamline showed that nanocrystalline layers form during the process, which increase material performance.