Speeding up CIGS solar cell manufacture

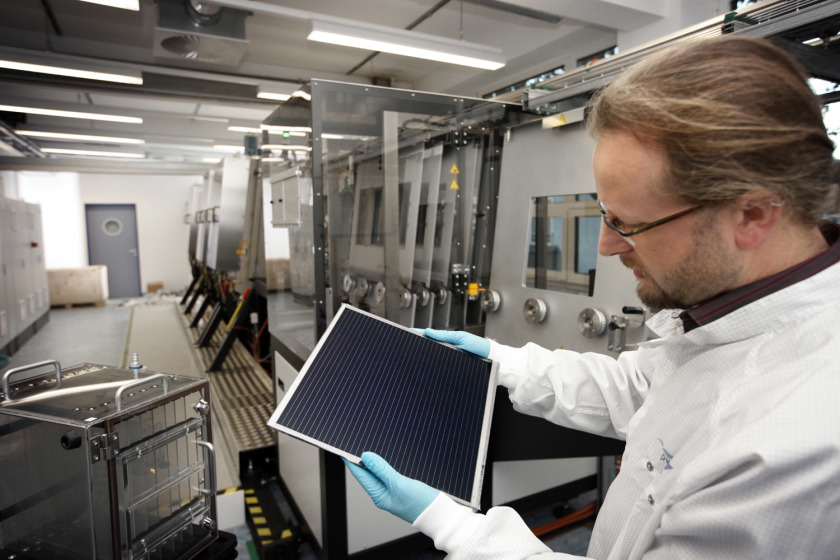

The funding will go towards optimising a co-evaporation process at PVcomB used for producing CIGS layers for thin-film solar cells. Photo: HZB

The CIGS thin film photovoltaics can be integrated pleasingly into building architectures. Photo: Manz AG

Speeding up CIGS solar cell manufacture

A project consortium from research and industry involving the Competence Centre for Photovoltaics Berlin (PVcomB) of Helmholtz-Zentrum Berlin has been granted a major third-party-funded project by the Federal Ministry of Economics. The project “speedCIGS” is to be funded with 4.7 million euros over four years, of which 1.7 million goes to HZB. The project partners will use this money to accelerate the manufacturing process for CIGS thin-film solar cells and thus make the technology more attractive to industry.

The speedCIGS project is being carried in cooperation with systems builder Manz AG, the Center for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW), the Universities of Jena and Paderborn, the Max Planck Institute Dresden and the Wilhelm Büchner Hochschule (as project coordinator).

The acquired funding will go towards optimising a co-evaporation process at PVcomB used for producing CIGS layers for thin-film solar cells. CIGS solar cells get their name from their constituent elements Copper, Indium, Gallium and Selenium. The elements are deposited together in a vacuum onto a heated substrate to form a thin layer of the desired compound. The manufacturing process used at PVcomB is already being used industrially, but is still relatively slow. The process is now to be sped up within the speedCIGS project, so that more modules can be produced per unit time for the same investment costs. This would make the production of CIGS solar modules much cheaper, giving the technology a competitive advantage in the currently tense market situation.

Also to be developed at PVcomB is a transparent p-conducting material that will go a long way towards developing high-efficiency tandem solar cells based on CIGS.

Polycrystalline CIGS solar cells already stand out for their high efficiency and high energy yields. Another advantage is the aesthetic appearance of the modules, which integrate pleasingly into building architectures.

(sz/il)

https://www.helmholtz-berlin.de/pubbin/news_seite?nid=14566;sprache=en

- Copy link

-

BESSY II: Heterostructures for Spintronics

Spintronic devices work with spin textures caused by quantum-physical interactions. A Spanish-German collaboration has now studied graphene-cobalt-iridium heterostructures at BESSY II. The results show how two desired quantum-physical effects reinforce each other in these heterostructures. This could lead to new spintronic devices based on these materials.

-

Green hydrogen: MXenes shows talent as catalyst for oxygen evolution

The MXene class of materials has many talents. An international team led by HZB chemist Michelle Browne has now demonstrated that MXenes, properly functionalised, are excellent catalysts for the oxygen evolution reaction in electrolytic water splitting. They are more stable and efficient than the best metal oxide catalysts currently available. The team is now extensively characterising these MXene catalysts for water splitting at the Berlin X-ray source BESSY II and Soleil Synchrotron in France.

-

SpinMagIC: 'EPR on a chip' ensures quality of olive oil and beer

The first sign of spoilage in many food products is the formation of free radicals, which reduces the shelf-life and the overall quality of the food. Until now, the detection of these molecules has been very costly for the food companies. Researchers at HZB and the University of Stuttgart have developed a portable, small and inexpensive 'EPR on a chip' sensor that can detect free radicals even at very low concentrations. They are now working to set up a spin-off company, supported by the EXIST research transfer programme of the German Federal Ministry of Economics and Climate Protection. The EPRoC sensor will initially be used in the production of olive oil and beer to ensure the quality of these products.